Melting Points of iron Oxides

* Final gross prices may vary according to local VAT.

Abstract

Lump lime as a flux material in a basic oxygen furnace (BOF) often creates problems in operation due to its high melting point, poor dissolution property, hygroscopic nature, and fines generation tendency. To alleviate these problems, fluxed lime iron oxide pellets (FLIP) containing 30% CaO were developed in this study using waste iron oxide fines and lime. The suitable handling strengths of the pellet (crushing strength: 300 N; drop strength: 130 times) of FLIP were developed by treating with CO2 or industrial waste gas at room temperature, while no separate binders were used. When the pellet was added into hot metal bath (carbon-containing molten iron), it was decomposed, melted, and transformed to produce low melting oxidizing slag, because it is a combination of main CaO and Fe2O3. This slag is suitable for facilitating P and C removal in refining. Furthermore, the pellet enhances waste utilization and use of CO2 in waste gas. In this article, emphasis is given on studying the behavior of these pellets in hot metal bath during melting and refining along with thermodynamics and kinetics analysis. The observed behaviors of the pellet in hot metal bath confirm that it is suitable and beneficial for use in BOF and replaces lump lime.

You might also like

|

Twinlab Magnesium 400mg Capsules, 240 Count Health and Beauty (Twinlab)

|

|

Nature Made High Potency Magnesium 400 Mg, 60-Count Health and Beauty (Nature Made)

|

|

NOW Foods Magnesium Capsules, 180 Capsules / 400mg Health and Beauty (NOW Foods)

|

|

KAL - Magnesium Glycinate 400, 180 tablets Health and Beauty (Kal)

|

|

Bluebonnet Nutrition, Magnesium Asparate 400 mg , 200 Vcaps Health and Beauty (Bluebonnet)

|

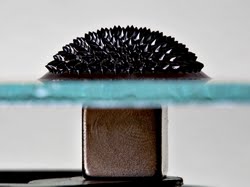

A ferrofluid (portmanteau of ferromagnetic, and fluid) is a liquid which becomes strongly magnetized in the presence of a magnetic field.

A ferrofluid (portmanteau of ferromagnetic, and fluid) is a liquid which becomes strongly magnetized in the presence of a magnetic field.